It’s always a pleasure to take the A112 Abarth for a spin, and only those who have driven it know how the famous phrase by Karl Abarth, translates into practice.

There’s pleasure in humiliating higher-class and pricier cars with a modest utility vehicle

We’ve often been amazed by the engine’s performance with just small tweaks, which can’t be compared to more robust preparations. The question arises: is it just a feeling you get when driving, or can the engine be improved with a small but effective tune-up?

A112 Abarth Cylinder Head Development

Optimizing the intake tract is one of the most effective ways to improve engine performance. It doesn’t require significant investments, doesn’t need maintenance, and provides good returns for the effort. In this section, we’ll share some results from years of research and testing (expensive ones, too), which are now the technical foundation of our workshop.

Introduction to Preparing the A112 Abarth Cylinder Head for Stock Engines

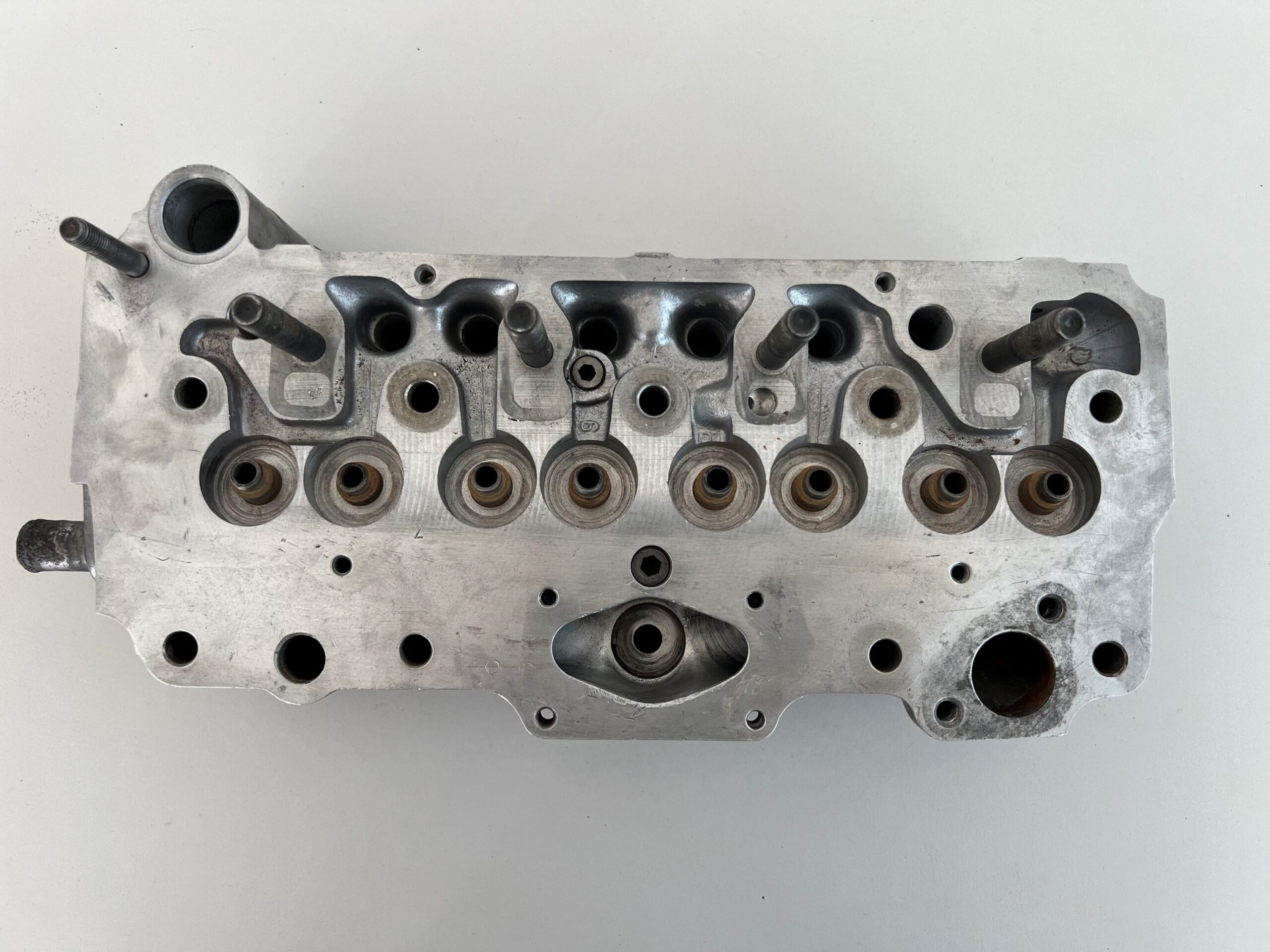

The cylinder head of the 100GL and derived engines is a paragon of constructive simplicity, economy, and longevity.

With its 70mm height and intake manifold integrated into the head itself, it’s not exactly a head with sporting ambitions. However, as often happens, necessity becomes virtue. The A112 Abarth 70hp engines have always done their job well, even if not all 70hp declared were always present.

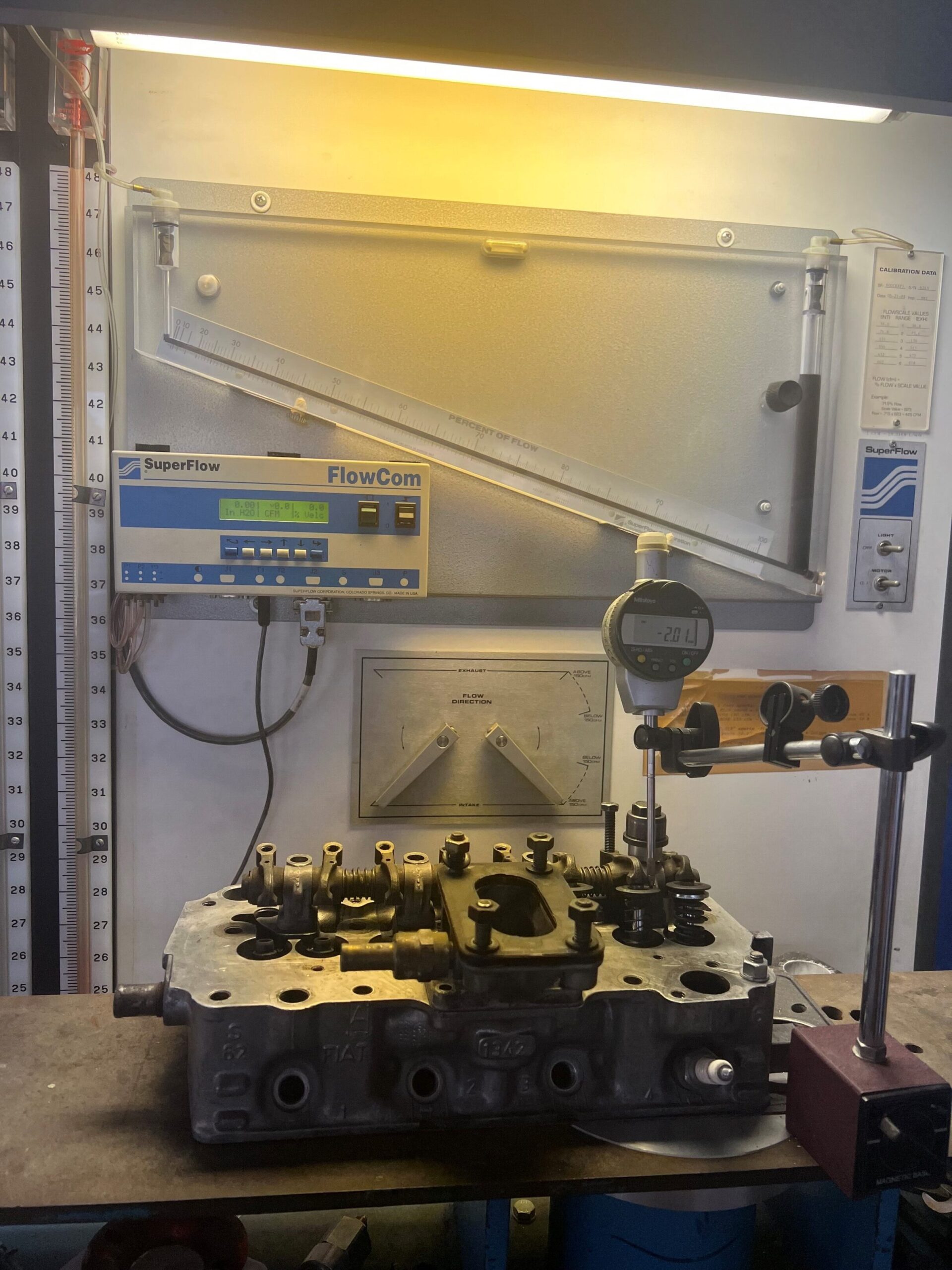

Flow Bench Analysis

Premise

Before diving into the results, we need to outline some premises to define the analysis domain and testing methods. The baseline data concerns original heads, with valves having the same dimensions and geometry as the originals, and the intake port between the manifold and head having standard dimensions. The characterized components are the intake tract, head, and intake manifold.

All results we’ll see are the outcome of multiple tests conducted over the years to guarantee robustness data

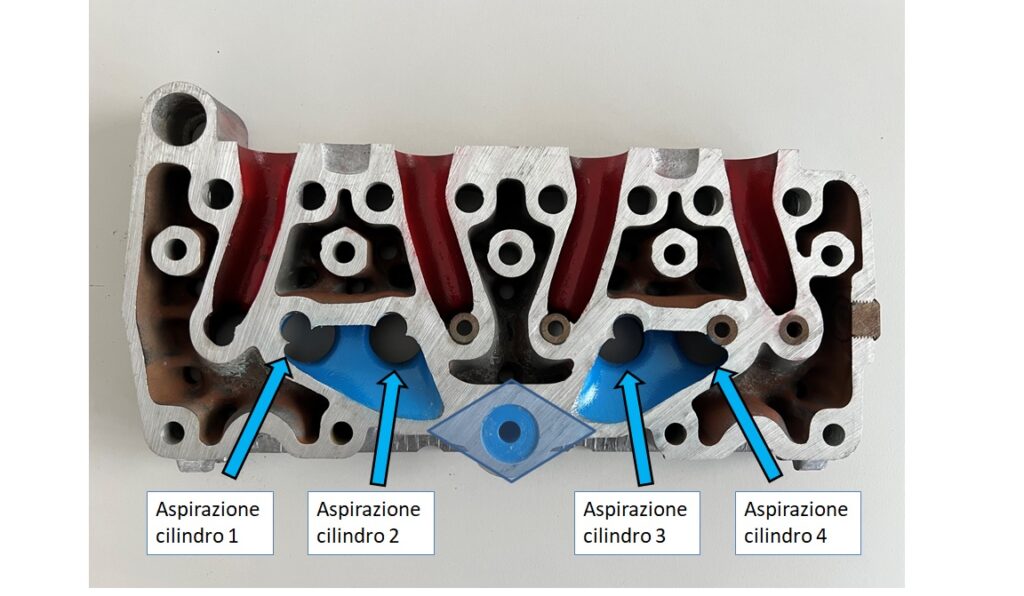

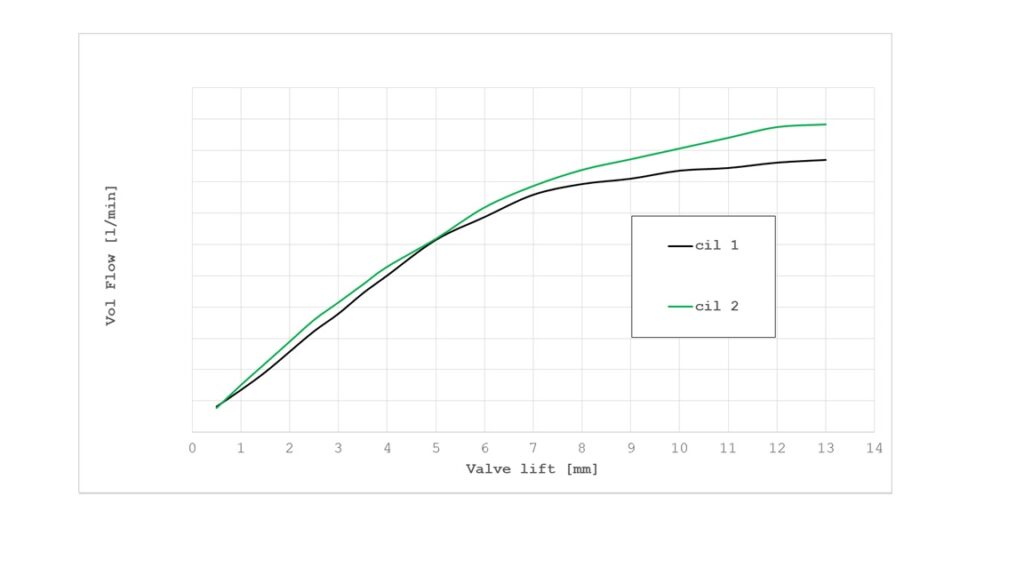

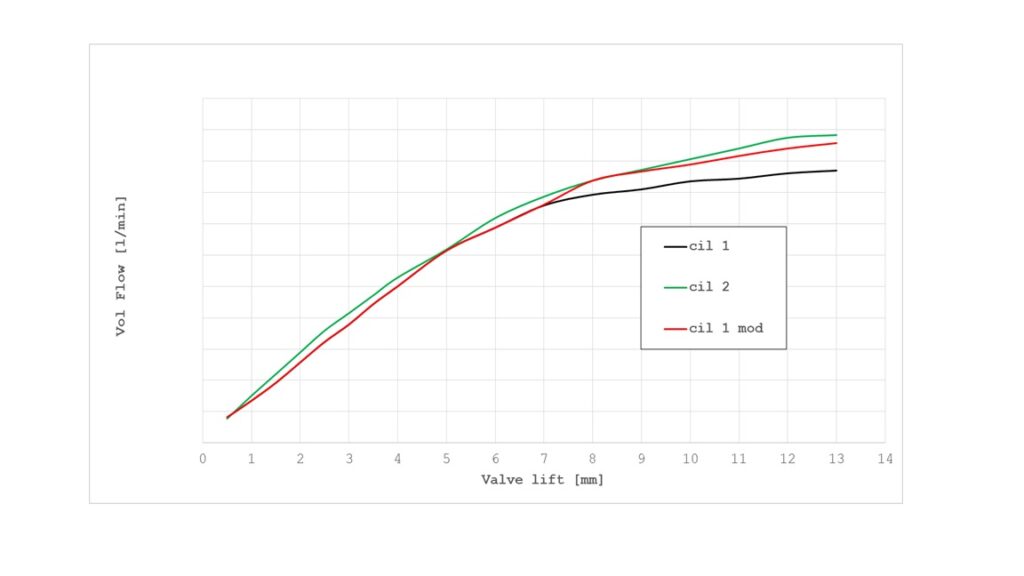

The graphs show the airflow rate (on the y-axis) versus valve lift (on the x-axis). The flow rate scales have been intentionally removed for data confidentiality. In the analysis, we’ll refer to cylinders 1 and 2 for simplicity. Cylinders 3 and 4 show similar results. The tests were conducted by testing one cylinder at a time.

Now, let’s proceed to evaluate the data.

Original A112 Abarth 70hp Head

The stock head shows an evident geometric imbalance in intake port length between the intake valve position of cylinder 1 and cylinder 2.

It’s easy to imagine that the port farthest from the central intake entrance has more flow losses and thus struggles to receive air.

After a 7mm valve lift, a significant divergence in flow rates between cylinders 1 and 2 becomes apparent.

This difference in cylinder feeding is also visible when the engine is running. The most attentive observers might have noticed that when changing spark plugs, the coloration of those in the outer cylinders (1 and 4) always appears leaner compared to the central cylinders (2 and 3).

Modified Head with Flow Balancing towards Outer Cylinders

Given the situation, the goal is to equalize flow rates across all cylinders. After years of testing, we’ve developed a good ability to modify heads for this purpose. The process involves creating a preferential path for airflow towards the outer cylinders by removing material, taking care not to exceed into the cooling liquid chamber. This work is quite challenging and can only be done with a manual die grinder, requiring thin-shanked tools and a lot of patience.

The red curve describes the new airflow rate trend on cylinder 1, which is virtually superimposed on that of cylinder 2 up to a 13mm lift. For a stock engine with a lift of about 9.5mm, the projected power increase corresponds to approximately 5hp.

Conclusion and Future Developments

I imagine many are wondering: is the result confirmed in practice? Is the projected data real? Certainly, as many of you know, every statement we make is documented.

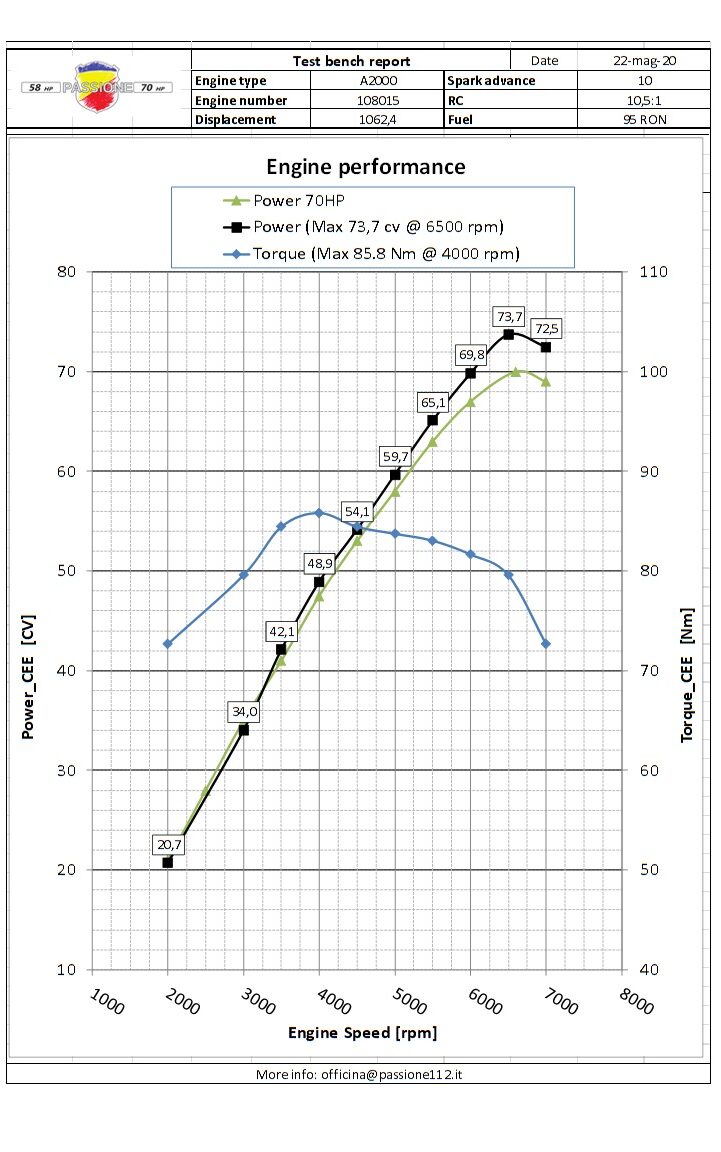

Below is a power curve of a completely stock 70hp engine, except for the head work, which the client chose to include. The graph shows the characteristic curves of our engine compared to the declared power curve for the 70hp engine. The maximum power recorded is 74hp, while the maximum torque is 85.8 Nm.

From our experience with rebuilt and tested engines, the average maximum power is 68hp. Based on these considerations, the 6hp difference between the base engine and the modified version confirms the flow bench prediction.

This fine-tuning activity is definitely a plus for the A112 Abarth engine, and its contribution would be even more evident if one were to increase the valve timing with more performance-oriented camshafts.

Next step…?! There’s definitely room to further increase this result, but for a significant power step, replacing the valves and seats with larger ones is necessary. The modification of ports, seats, and valves is, in fact, the preparation of heads for Group 2 A112 Abarth cars still

Thanks for your attention and let’s keep in touch!!

For any questions, feel free to contact us at our email Officina@passione112.it or WhatsApp

Fascicolo prodotto da: Passione 58 70 – Area Motori (rev.1 35/2025) – ogni riproduzione parziale o totale del testo e delle immagini é vietata